History

General Logic was established in 1998 by Daniele Lugli and Franco Sartorio.

Daniele Lugli graduated in Nuclear Engineering with an experimental

thesis at Euratom. He then worked with industrial diagnostic expert

systems, directed the software group of Fidia (producers of numerical

controllers for milling) and coordinated the technical group of Prima

Electronics in the development of the PRIMACH numerical controller for

robots and laser cutting machines.

Franco Sartorio has been an important figure in Piedmontese and Italian

entrepreneurship. Graduated in electrical and mechanical engineering,

founder of DEA and of the Prima Group, holder of several mechatronic

patents, he has been the father of the contact measuring machine.

The PAG and Sentinel measuring machines designed by Sartorio remained in

use by hundreds of enthusiastic customers who did not want to replace

them even when electronic spare parts were no longer available.

The original mission of General Logic was therefore to create a modern

numerical controller for the retrofit of these machines, preserving the

large libraries of part programs developed by customers; so was

born VCNC, one of the first NCs based on Personal Computer, and so General Logic has been able to accumulate a large experience in the field of metrology.

with VCNC control unit (on the left).

OptiMe

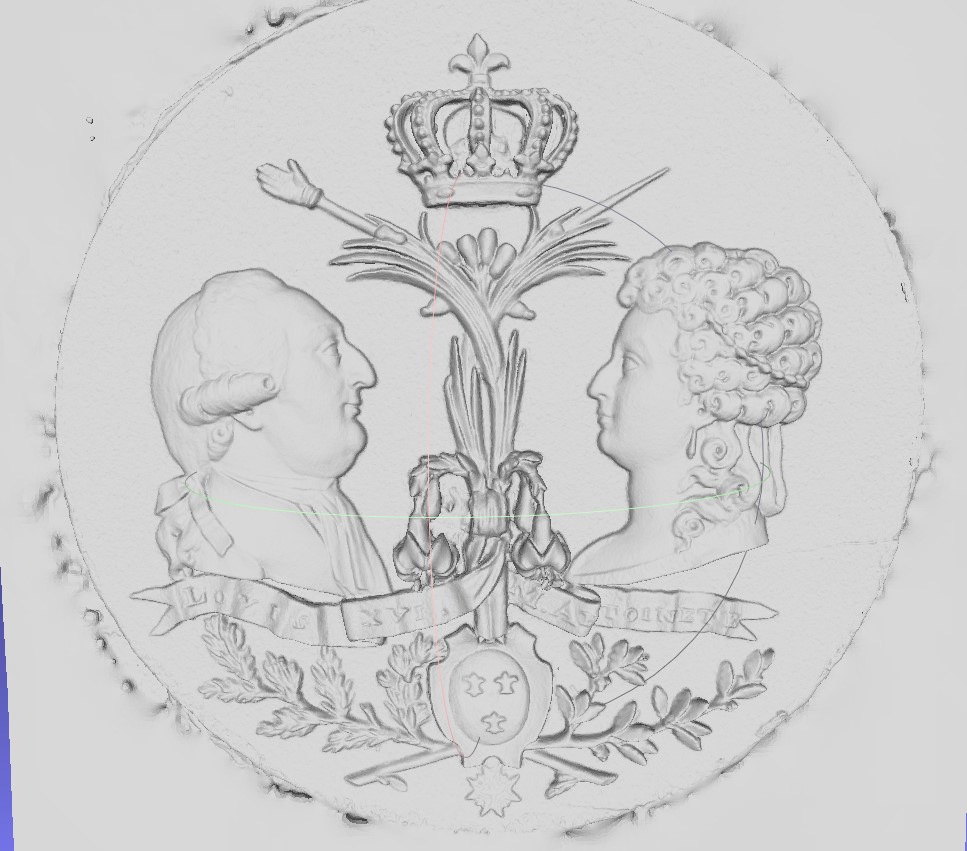

Soon General Logic realized the potential of optical measurement and began developing OptiMe (Optical Measurement, but also very well in Latin).

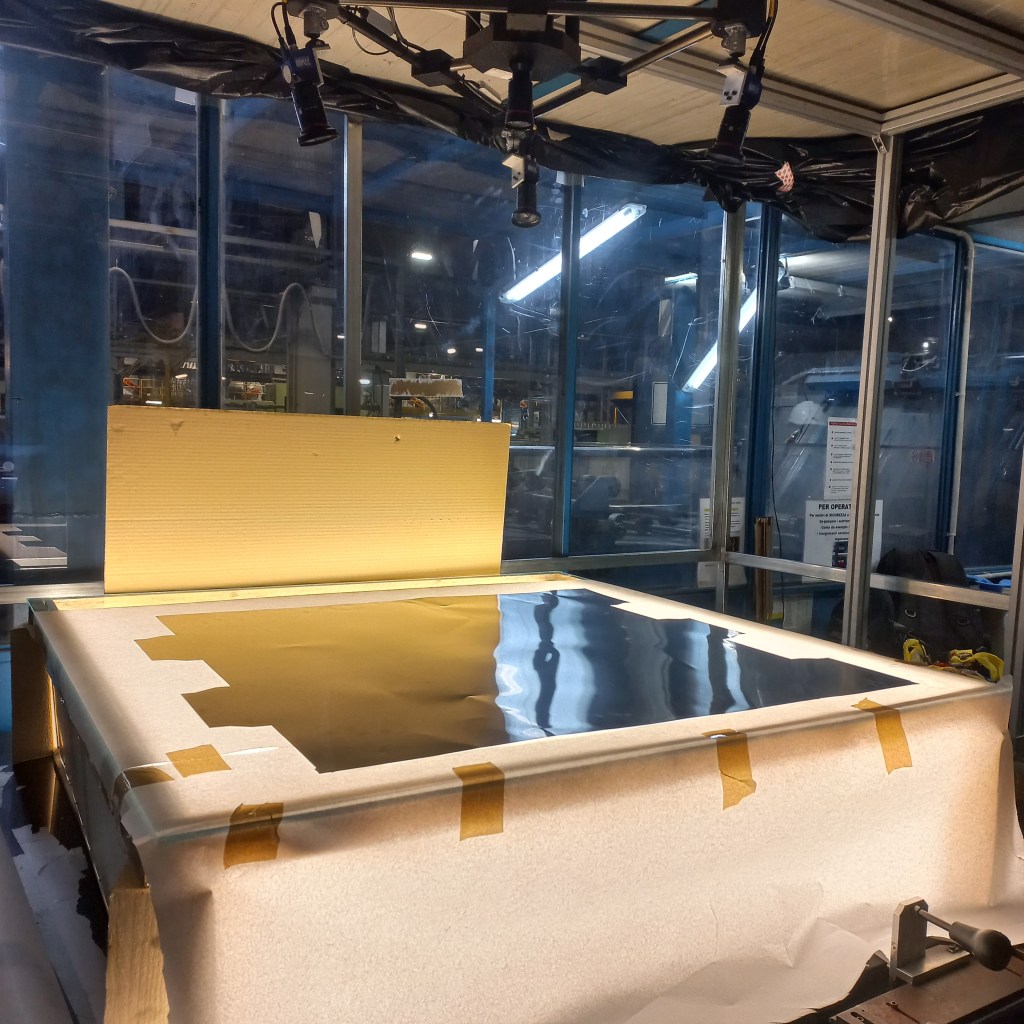

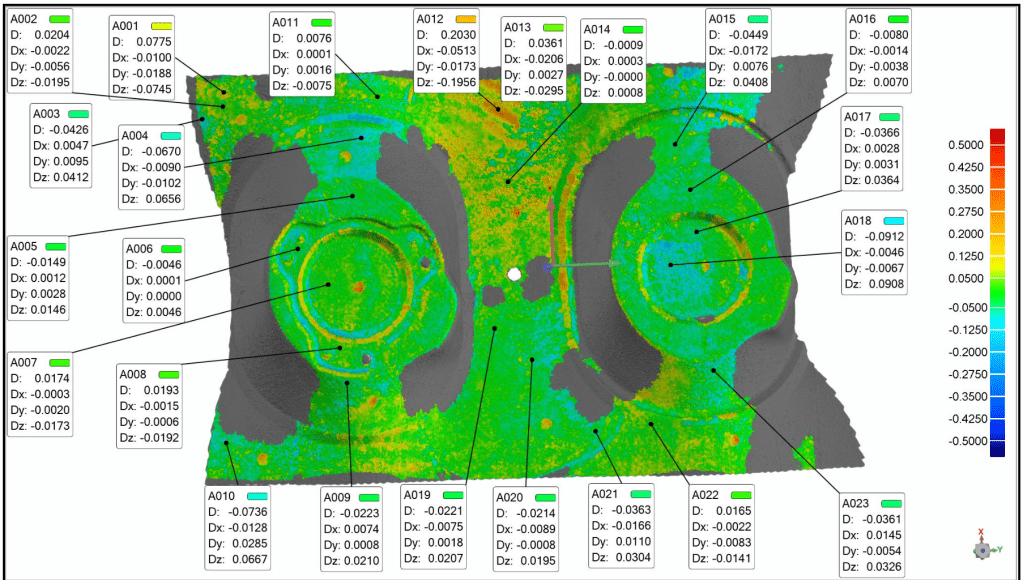

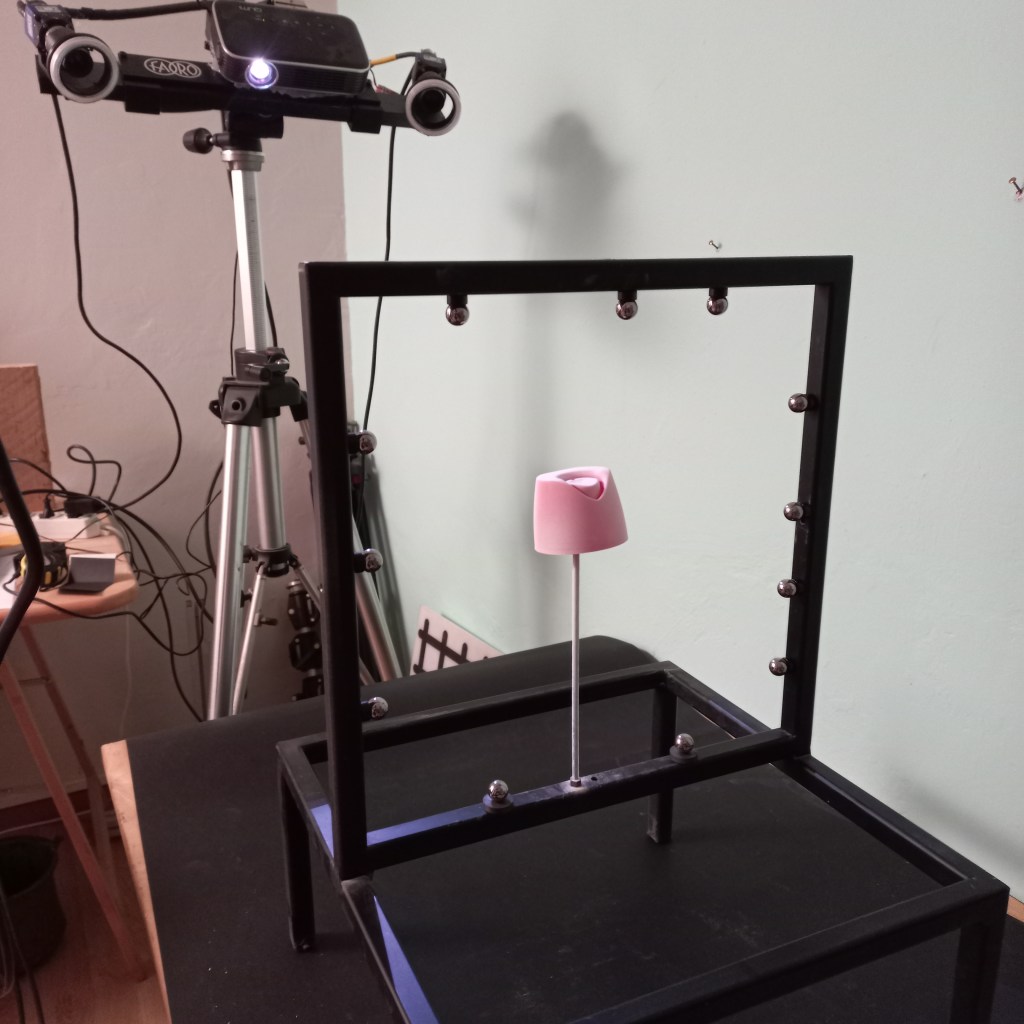

OptiMe is a 3D scanner based on the projection of a sequence of structured light patterns, acquired by two cameras (in the model called Bino) which are fixed on a rigid support.

Comparison with commercial scanners shows fully overlapping results.

and with a laser arm.

Depending on the configuration (distance between the cameras; their

orientation; focal length of the lenses) OptiMe can scan objects of

different sizes.

Innovation

OptiMe offers innovations not easily found in similar systems:

with taut, rectilinear wires. If the lens distortions are correctly compensated, the wire images appear straight.

C-OptiMe

In 2018 Fratelli Rotondi srl of Legnano, manufacturers of contact

measuring machines and optical scales, acquired a stake in General

Logic. One of the fruits of this synergy is C-OptiMe (Collaborative OptiMe).

OptiMe Trio

The use of three cameras, instead of two as in the Bino model, allows

for some additional possibilities. If in Bino it is necessary to project

a sequence of patterns to make the points on the surface identifiable,

so that they can be reconstructed, the third camera allows for

identification and reconstruction even with a single random pattern

projected. This means reducing scanning times and the risk of the object

moving during acquisition; Trio could also be used as a handheld

scanner. For this reason, General Logic and Fratelli Rotondi are

developing Trio, the new trinocular model of OptiMe.

Another possibility offered by the trinocular system is to detect the

edges of flat objects regardless of their orientation, while a binocular

system cannot correctly acquire edges parallel to the line connecting

the two cameras.